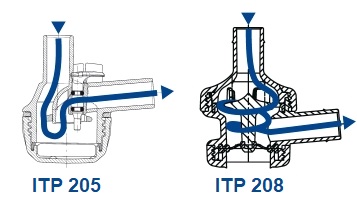

ITP205 - ITP208

ITP205-208 are individual milking claws incorporating unique automatic shut-off valves which automatically control the vacuum supply to each liner during both milking and washing.

As soon as the teat enters the liner, the valve automatically opens. Then, when the teat is removed at the end of milking, rapid air intake creates a vacuum in the valve which automatically closes it.

This offers a range of benefits:

-

Fewer operations both during milking.

-

Less vacuum fluctuation

-

when liners are fitted and removed, thus avoiding undesirable consumption of vacuum and suck up of dirt.

-

Valves close automatically if the cluster is kicked off.

-

An unhealthy teat can be isolated during milking.

-

Easy to inspect for cleaning and maintenance.

-

High impact resistant materials are used to construct the milking claw.

ITP205

-

Fit the liner to the teat and the valve automatically opens. When you have finished milking, just pull the liner slightly to detach the unit: this lets in air which closes the valve.

-

During washing the lever must be pushed down to prevent the valve from closing due to the water turbulence.

ITP208

-

Fit the liner to the teat and the valve automatically opens. When you have finished milking, just pull the liner slightly to detach the unit: this lets in air which closes the valve.

-

Washing is fully automatic.

ITP208 starts "normally closed", to prevent vacuum leakages at the activation of the Milking machine.

ITP 208 has been designed for automatic systems, with high washing flow rates.

- It supports washing flow rates above 15L/min at 50KPa

- It shuts off before cluster attachment, preventing excess air and bacteria from entering the teat prior to milking.

- All materials directly in contact with milk are approved by both EU and US food safety regulations.

| КОД | ОПИСАНИЕ | |

|---|---|---|

|

2059023 | Set ITP205 PSU System (10X2059022) |

|

2089020 | Set ITP208 System MAN (10X2089019) |

|

2089030 | Set ITP208 Sistema Autom. CLS VENT (10X2089029) |